Cut your overnight blots down to a single workday while boosting reproducibility

1 Why Western blotting still hurts

Despite its status as the gold-standard for validating protein expression, the classic workflow is dogged by:

|

Pain point |

Typical cause |

Impact |

|---|---|---|

|

Time-to-result |

Overnight antibody incubations plus long transfer runs |

≥ 16 h turnaround |

|

Transfer inefficiency & overheating |

Wet-tank transfers at 100 V for ≥ 1 h |

Patchy bands, distorted high-MW proteins |

|

Hands-on variability |

Manual blocking/wash cycles |

User-to-user CV > 20 % in band intensity |

|

Antibody cost |

Large incubation volumes, single use |

Primary Ab spend can exceed SGD 5 k/yr/lab |

|

Dynamic-range limits |

Film or narrow-range CCD imagers |

Weak bands lost; strong bands saturated |

2 Technology advances that shrink the workflow

|

Workflow segment |

Recent innovation |

Time saved |

Key benefit |

|---|---|---|---|

|

Gel run |

Pre-cast gradient or stain-free gels (Bio-Rad TGX Stain-Free, Bolt Bis-Tris) |

30–40 min |

No casting; fluorescence imaging of total protein for loading control |

|

Protein transfer |

Semi-dry rapid transfer – Trans-Blot Turbo (3 min) ; Dry transfer – iBlot 3 (≤ 7 min) |

≥ 50 min |

Less heat, consistent high-MW recovery |

|

Blocking / Ab incubations |

Automated processors (e.g., Bandmate, SNAP i.d) recycle antibodies and run unattended |

1–4 h |

Up to 90 % hands-on reduction; 3-fold Ab economy |

|

Detection |

Near-IR imagers (LI-COR Odyssey DLx) give 6-log dynamic range; capillary “blots” (Bio-Techne Jess) finish in ≈ 30 min |

≥ 1 h |

True quantitation, multiplex two targets at once |

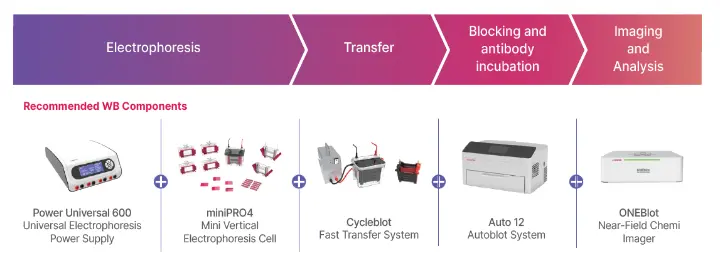

3 Putting it together: the integrated 5-hour workflow we distribute

By chaining the fastest option in each segment, a complete blot—including imaging and densitometry—fits comfortably inside a standard workday:

|

Step |

Module (generic) |

Runtime |

|---|---|---|

|

SDS-PAGE (4-gel mini tank, 200 V) |

45 min | |

|

Rapid semi-dry transfer (pel-tier cooled) |

20 min | |

|

Automated block → 1 h primary (37 °C) → 15 min secondary |

90 min | |

|

Near-field chemiluminescent or IR imaging + analysis |

5 min | |

|

Total bench-to-result |

≈ 4 h 45 min |

How it fixes the pain points

- 70 % faster than the legacy 16 h protocol.

- Uniform transfer mitigates “smiling” and overheating artefacts.

- Closed-loop incubations cut antibody use by up to 5-fold.

- 6-log detection range means both faint PTMs and abundant housekeeping bands sit in the linear zone.

4 Technical tips & troubleshooting

- Sample prep: Keep lysates ≤ 4 °C; spin 16 000 g, 15 min to remove debris.

- Gel % logic: 4–20 % gradient for unknowns; 8 % for 70-250 kDa; 12 % for < 30 kDa.

- Voltage ramp: Start gels at 80 V until the dye front stacks, then jump to 200 V to finish in < 45 min.

- Membrane choice: PVDF for hydrophobic or low-MW proteins; rinse briefly in methanol then transfer buffer.

- Rapid transfer packs: Pre-wet membrane and stack only once to avoid air bubbles—major cause of uneven bands.

- Automated processor set-up: Use 3–5 mL/block (mini blot) and enable “antibody recovery” to reuse primaries 3 ×.

- Imager QA: Run the built-in glow-ladder once per quarter; check that R² > 0.99 across the intensity range.

- Quantitation best practice: Always normalise to total-protein stain (stain-free or REVERT total-protein IR stain) instead of housekeeping genes for higher accuracy.

References

- Bio-Rad Laboratories. The Complete Guide to Stain-Free Western Blotting (2024).

- Thermo Fisher Scientific. iBlot 3 Dry Blotting System Manual (2024).

- Bio-Rad Laboratories. Trans-Blot Turbo Transfer System product page (accessed 24 May 2025).

- Thermo Fisher Scientific. Bandmate Automated Western Blot Processor specifications (accessed 24 May 2025).

- LI-COR Bio. Odyssey Imager Family overview (accessed 24 May 2025).

- Bio-Techne. Jess Automated Western Blot System – Benefits and Workflow (2025).

- Tanabe L. The Ultimate Quick Tips & Tricks Guide to Western Blots. Biocompare, 9 May 2024.